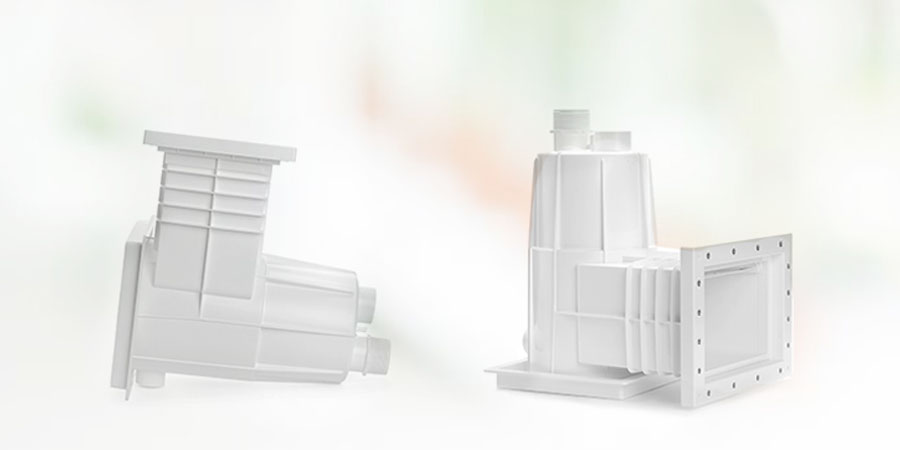

white goods

- Solutions

- White Goods

Sheet Metal Fabrication in White Goods

Sheet metal fabrication plays a crucial role in the manufacturing of white goods, providing the structural components and aesthetic appeal for appliances like refrigerators, washing machines, and ovens. Precision and quality are paramount, as these products are expected to be durable, functional, and visually appealing.

Key sheet metal operations for white goods include:

Cutting

Laser cutting, CNC punching, and shearing are employed to create precise blanks and intricate shapes from sheet metal. Material selection is critical, often involving steel (coated or uncoated), stainless steel, and aluminum, chosen for their strength, corrosion resistance, and formability.

Forming

Bending, stamping, deep drawing, and roll forming are used to shape the sheet metal into required components like cabinets, doors, panels, and internal structures. Complex shapes and tight tolerances are often necessary.

Welding

Welding (spot, MIG, TIG), riveting, clinching, and adhesive bonding are used to assemble multiple sheet metal parts into sub-assemblies and final products. Strong and reliable joints are essential for structural integrity.

Finishing

Surface treatments like powder coating, painting, plating, and anodizing enhance the appearance, durability, and corrosion resistance of the sheet metal components. Aesthetics are important for consumer appeal.

Sheet Metal Solutions for White Goods

Our expertise in these sheet metal operations enables us to provide white goods manufacturers with high-quality, cost-effective solutions. We offer design for manufacturing (DFM) support, ensuring efficient production and optimized designs. Our capabilities range from prototype development to high-volume production, meeting the demands of the white goods industry.