CAE/Design

- Product & Services

- CAE/Design

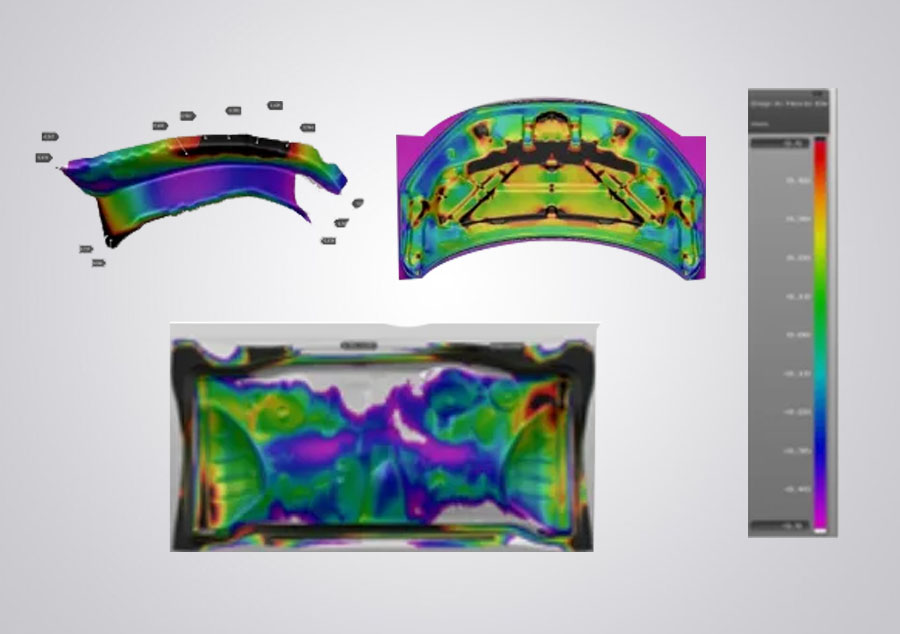

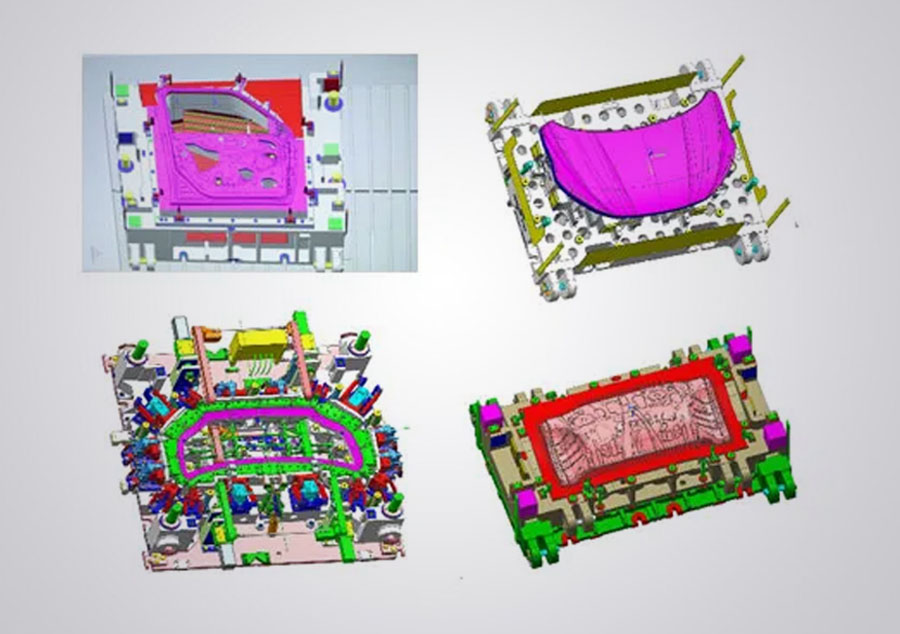

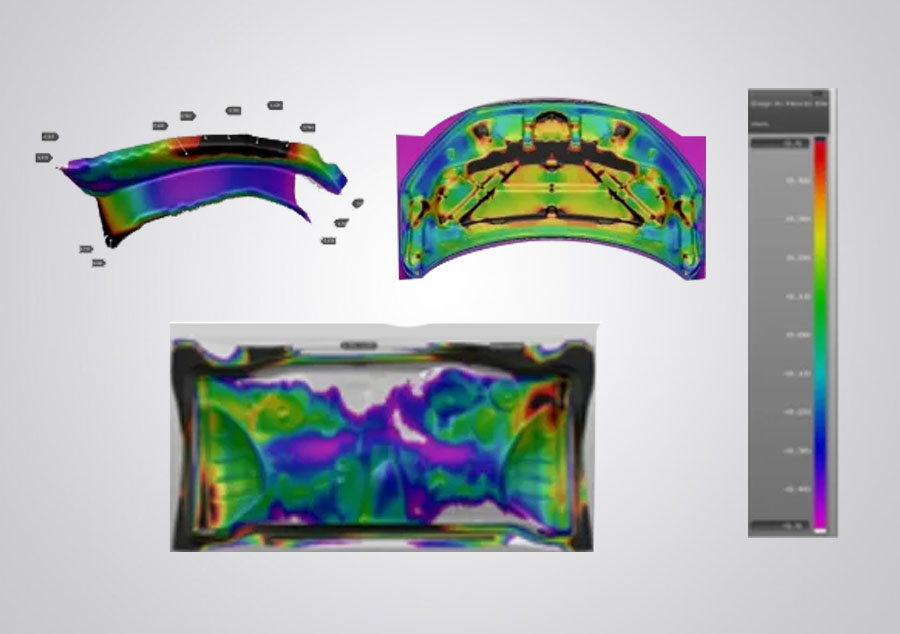

Our highly skilled design team collaborates closely with the engineering and manufacturing divisions to bring innovative ideas to life. Sheet metal designing is a meticulous process that involves transforming flat metal sheets into complex three-dimensional components or parts.

This is achieved using specialized software that enables precise modeling and design, taking into account crucial factors such as material properties, structural integrity, manufacturing feasibility, and functional requirements. By integrating advanced technology and industry expertise, we ensure that every design is optimized for performance, durability, and cost-effectiveness.

Key aspects of sheet metal design

3D Modeling

Creating accurate 3D models of the desired part using CAD software.

Material Selection

Choosing the appropriate metal (steel, aluminum, stainless steel, etc.) based on strength, weight, and cost.

3D Modeling

Creating accurate 3D models of the desired part using CAD software.

Manufacturing Considerations

Designing parts that are easily and efficiently manufactured using processes like bending, forming, cutting, and welding.

Tolerance Analysis

Ensuring that the design tolerances are within acceptable limits to ensure proper fit and function.

Drafting and Documentation

Creating detailed drawings and specifications for manufacturing and assembly.