UHSS - Ultra-High Strength Steels

- About Us

- UHSS - Ultra-High Strength Steels

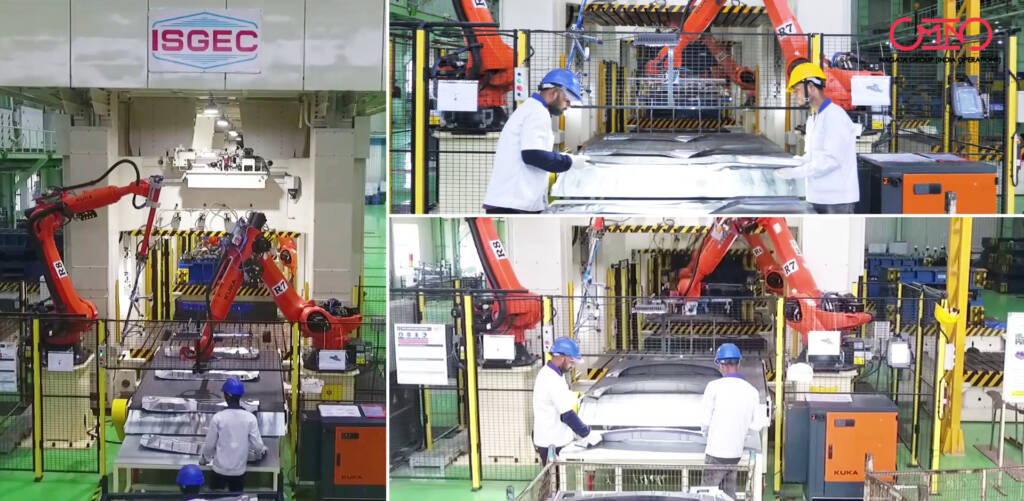

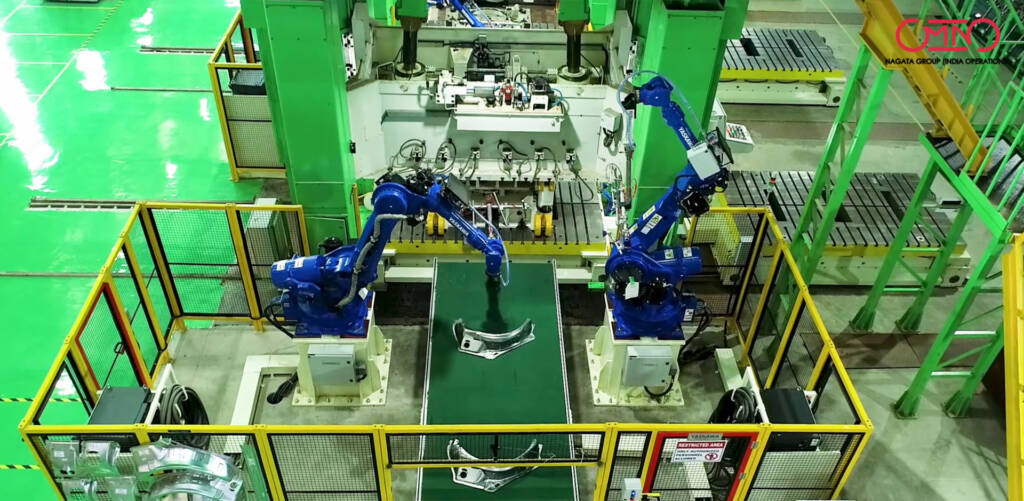

Nagata India is strategically positioned to leverage UHSS in critical automotive components. With state‑of‑the‑art stamping and welding operations across its three Indian plants (Manesar, Bilaspur, Sadatpura) , the company delivers:

Precision tooling for UHSS grades

Equipped with tandem, transfer, progressive, and cross‑bar press tool manufacturing, alongside high‑precision machining centers and trial presses—capable of handling high-strength sheet materials.

Advanced forming capabilities

Expertise in managing springback, formability, and dimensional accuracy of UHSS using 3D CAE/CAM tools and simulation-driven design.

Robotic SPM welding/assembly units: these are equipped to handle UHSS joining processes with tight tolerances and consistency, minimizing welding defects common with high‑strength materials.

Robust quality & compliance systems: Nagata India’s ISO/IATF, QMS, and HSE-certified operations ensure UHSS components meet OEM standards for safety-critical inner parts, outer skin parts, and structural assemblies.

By integrating cutting-edge equipment, simulation tools, and process automation, Nagata India delivers high-performance UHSS parts that support lightweight, durable, and safety-first vehicle designs—fostering competitive advantage in India’s evolving auto landscape.