Manesar, Haryana

- Mfg. Locations

- Manesar, Haryana

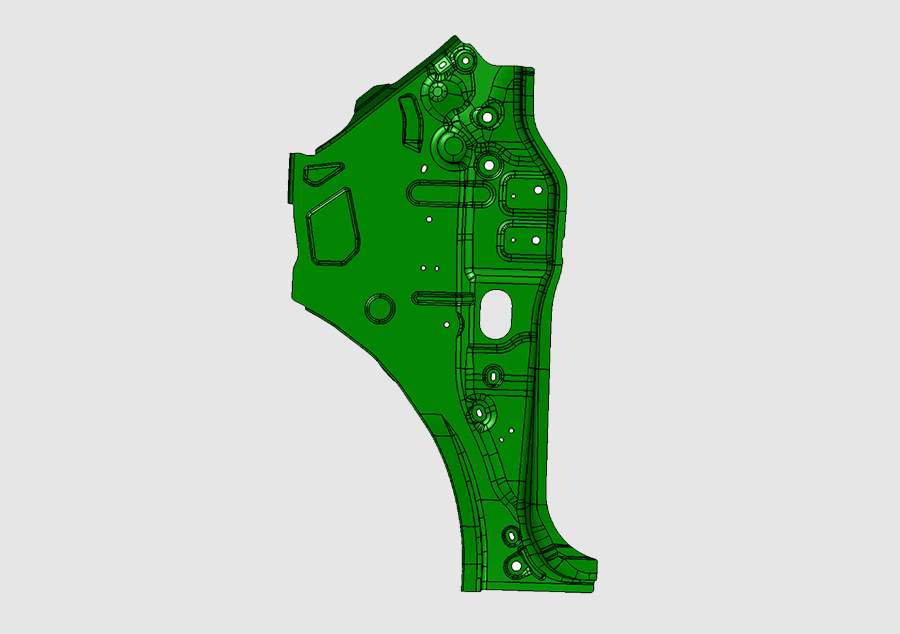

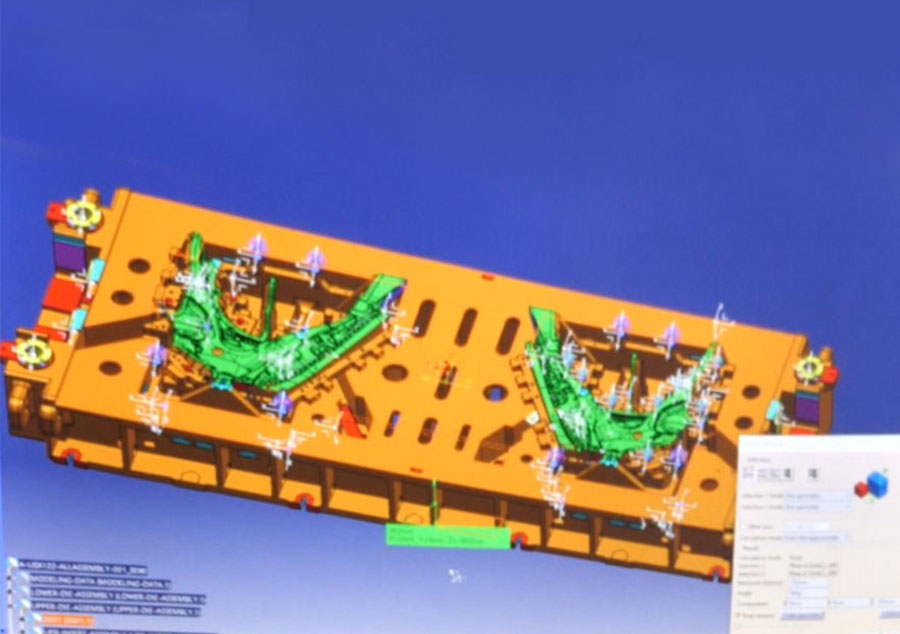

Nagata India is a leading provider of comprehensive sheet metal solutions , specializing in the design and manufacture of high-precision tooling and components. Our expertise encompasses the development of intricate tooling for various press types, including tandem, transfer, progressive presses. We cater to diverse customer needs, delivering solutions for critical inner parts, high-tensile components, skin parts, and hemming dies.

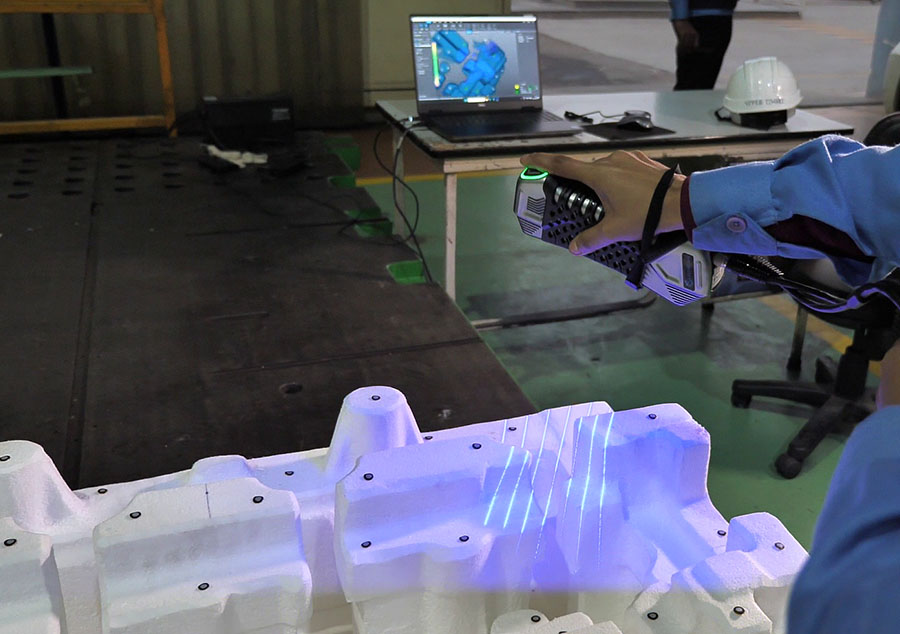

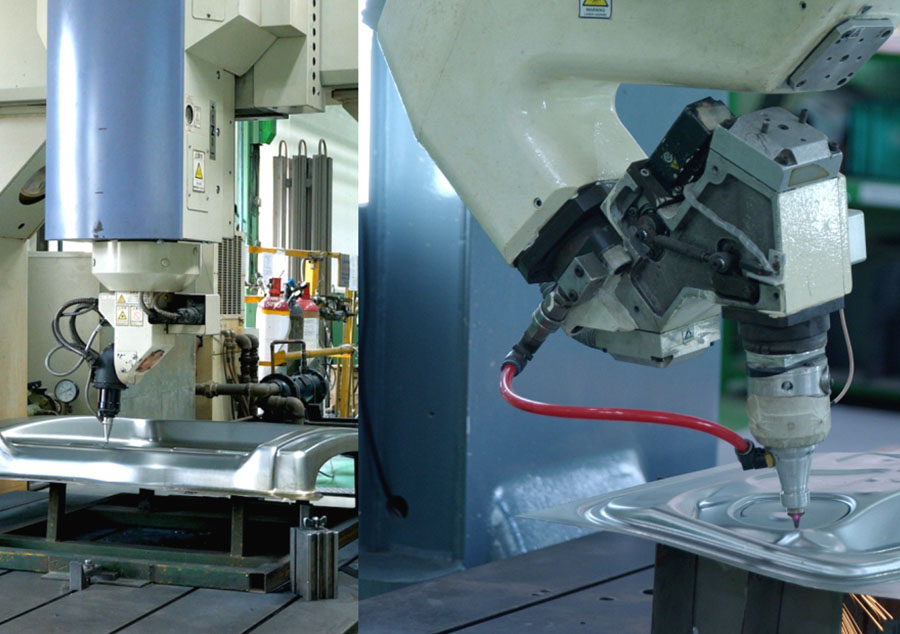

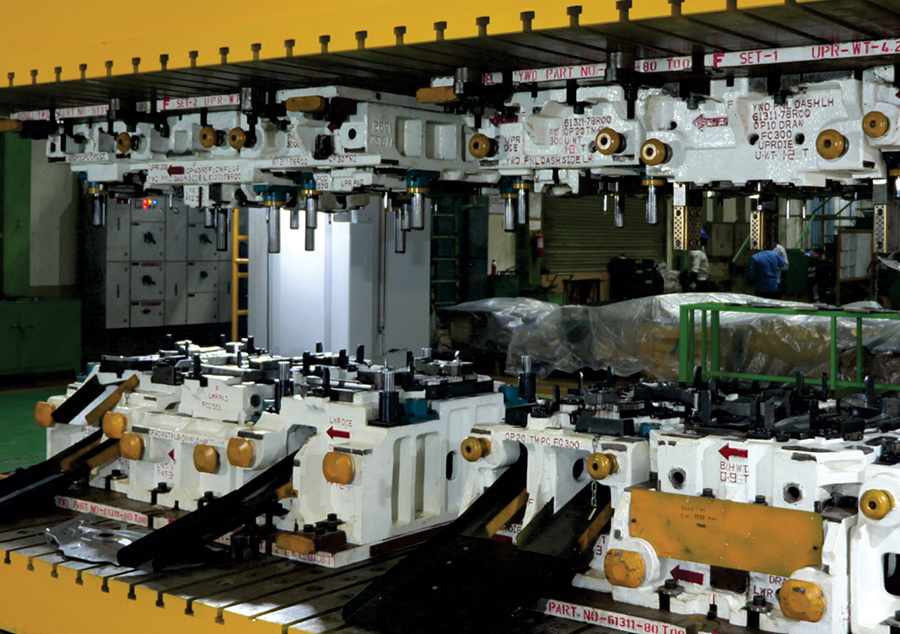

Our state-of-the-art manufacturing facilities are equipped with advanced technologies, including high-precision machining centers, a range of mechanical trial presses with varying capacities, and cutting-edge 3D software. These resources enable us to design and manufacture tooling with exceptional accuracy and efficiency.

This brings one of the best tooling facility which includes:

This brings one of the best tooling facility which includes:

- Expertise in tooling design and manufacturing: Emphasizes specialization in various press types and complex components.

- Advanced manufacturing capabilities: Showcases the use of high-precision machinery and 3D software.

- Comprehensive service offerings: Covers both tooling and component manufacturing.

- Focus on quality and cost-effectiveness: Highlights the commitment to delivering high-quality products at competitive prices.

- Strategic plant locations: Emphasizes the benefits of a strong manufacturing network.

simulation

Designing

Full Mould

CNC Machining

Laser Cut Machine

Inspection

Trial Presses

Dual Trial Press

2000 Ton

Trial Press

1000 Ton

Trial Press

2000 Ton

Trial Press

800 Ton

Trial Press

500 Ton

Trial Press

400 Ton

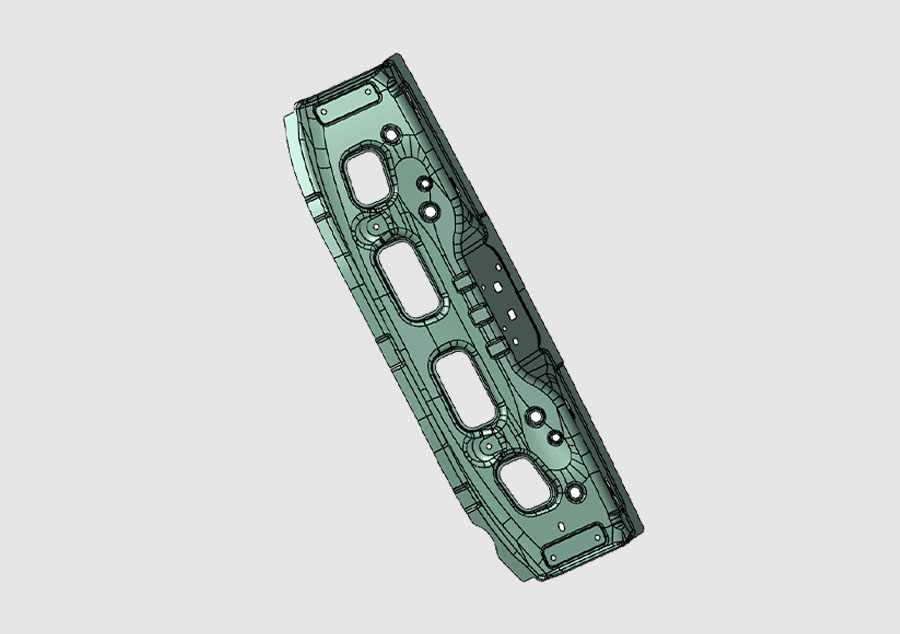

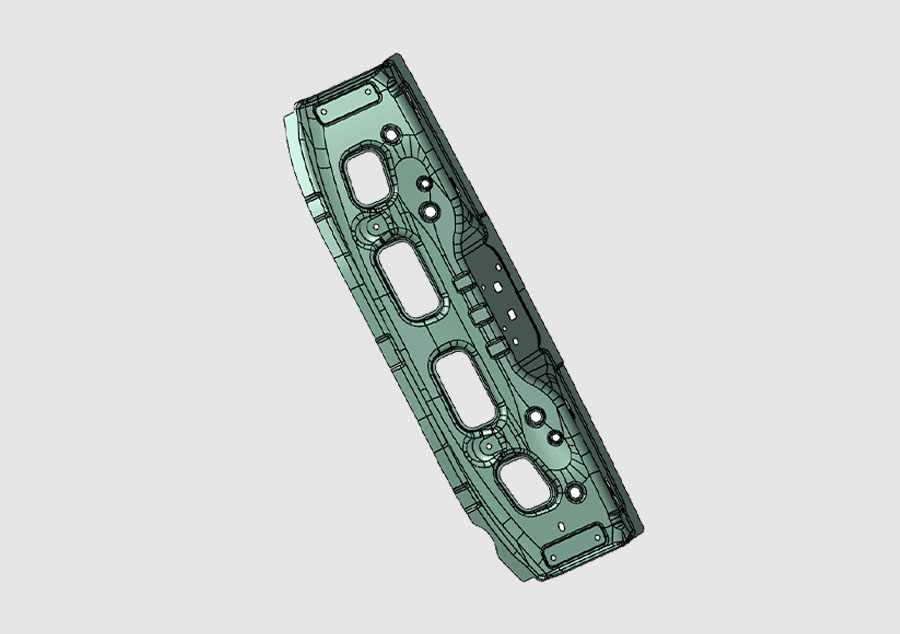

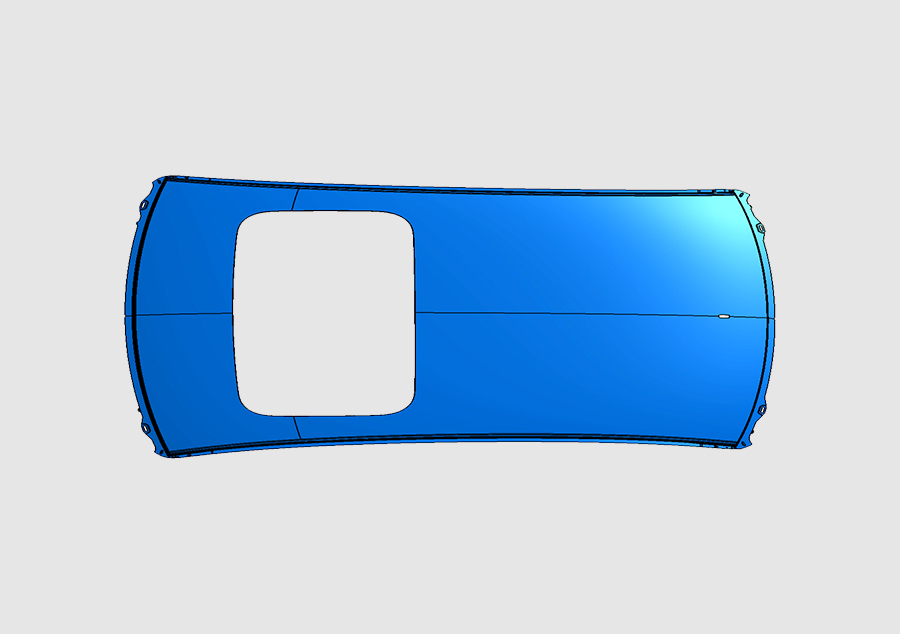

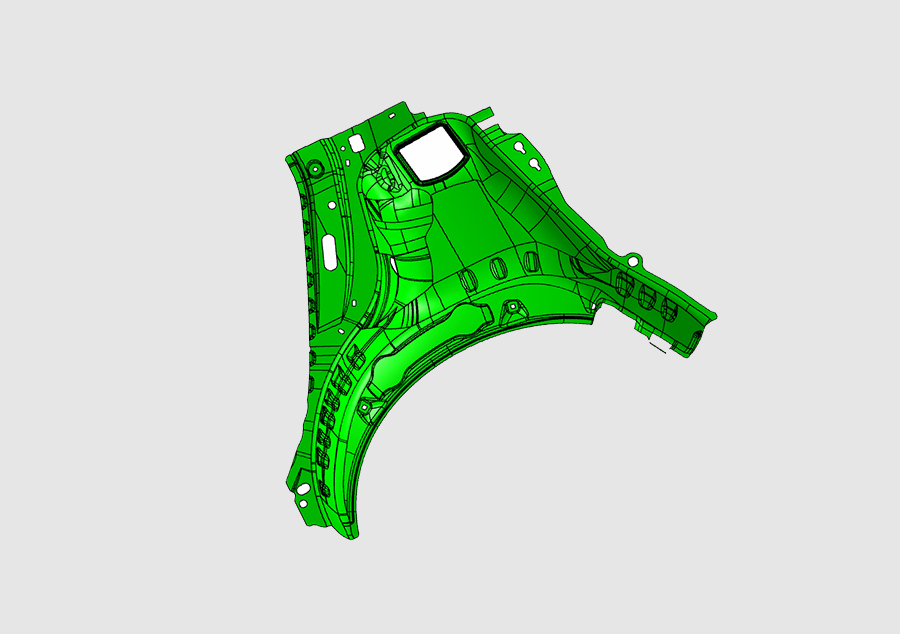

Product Portfolio

We possess the expertise in rapid prototyping capabilities is our in-house 5-axis laser cutting facility, enabling intricate and complex cuts on a variety of materials. From tooling to final assembly, streamlines the development process and delivers functional prototypes that meet your exact specifications.

Our Key Strength lies in:

- Rapid Development of Proto Tools.

- In-house Stamping of UHSS Parts.

- In-house 5 axis Laser Cutting Facility.

- Welding Facility to Make Proto Assembly.

Tail Gate Skin Uppe

Tail Gate Frame

Sunroof

Rear Inner

Panel Dash